Two Layer eva glass laminating machine For Architecture / Bending Laminated Glass

| Machine: | EVA Laminated Glass Machine | Usage: | EVA Laminated Glass Production |

|---|---|---|---|

| Layer: | 2 Layer | Max Glass Size: | 2000x3000mm |

| Max Glass Thickness: | 36mm | Production Capacity: | 72 Square Meter For One Cycle |

CE Certificate EVA Laminated Glass Manufacturing Machine with Excellent Vacuum Bag Stable Performance

Basic introduction of our laminated glass machine

Our EVA laminated glass machine works on the principle of vacuum and heating. After put the glass

in the vacuum bag, the vacuum system will help exhaust the air from the vacuum bag, create a vacuum

environment in the vacuum bag. This process ensure no bubbles appear between the glasses.,EVA Glass Laminating Heatbox,EVA Glass Laminating Furnace,EVA Glass Laminating Oven,Glass Lamination Oven for EVA Film Process,Laminating Furnace with EVA Film for Laminated Glass.

The heating system will melt the film so that the two pieces of glasses can be firmly stick together.

The composition of our laminated glass machine

Our laminated glass machine is mainly composed of the four systems:PLC control system,heating

system,vacuum system,insulation system.

The frame of the entire machine uses 10mm thick galvanized angle steel with CO₂gas shielded

welding. The surface of the machine is treated with varnish.Combined with the unique seamless welding,

our machine has very beautiful appearance, reasonable structure,very stable and durable.EVA Film Automatic Laminating Glass Machine,EVA Glass Laminating Machine,Vacuum Heating Machine,Laminated and Vacuum Machine,EVA Laminated Machine for Glass.

We adopt Germany technology with newly improvement, It’s specially designed for the dry glass

laminating. The heating element is changed from carbon fiber to 304 stainless steel heating tube,

make heating up and down distributed like carpet, formed a forced convection, heat up evenly and faster, and with longer lifetime. ONLY need 2~3 seconds for 1℃. And there turbo blower ensures hot air to circulate every corner, temperature inside the furnace is equal and temperature difference not exceed 3~5℃. The processing glass can get uniform heat for a high product yield. The heater wire now connected outside wall of the furnace, this can avoid damage caused by inside high heating temperature, and easier for maintenance of the machine.,EVA Film Laminating Machine for Glass,EVA Film Laminating Machine,Glass Laminating Machine with EVA Film,EVA Film Glass Laminating Machine.

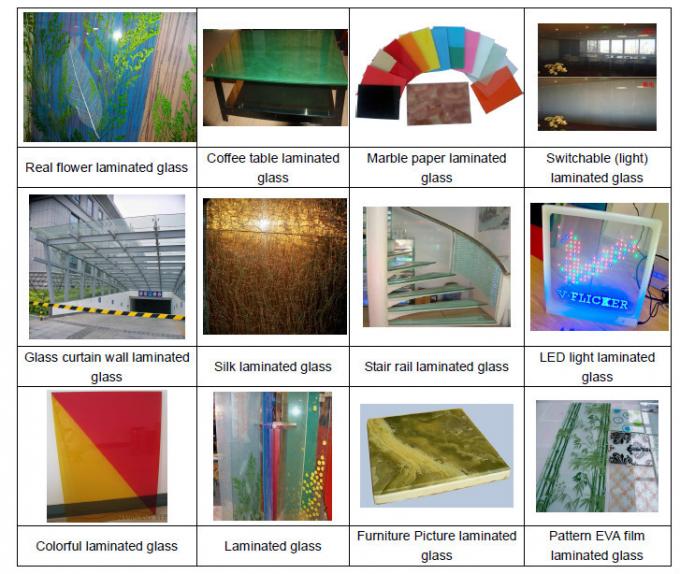

Our glass laminating machine can adopt EVA as interlayer to produce architectural laminated glass, top grade decorative laminated glass, bulletproof laminated glass, bending tempered laminated glass, fabric laminated glass, new energy laminated glass etc. The similar machines from other

local suppliers can do decorative lamination only. Our machine is first in China can process true flower

laminated glass.EVA Glass Laminating Heatbox /Furnace /Oven.

Our machine produces curved tempered laminating glass in one step, no need autoclave and

pre-pressing machine. Max bending height reaches 440mm. If you have autoclave, our

laminating glass equipment could work with it to produce curved safety glass easily and economically.

Application:

Glass Curtain wall, skylight, building glass, home furniture decoration, stairs and railings, shower room, glass windows & doors, indoor partition, solar PV panel, PDLC/LED laminated glass,

coffee table etc.

Condition: New

Machine Type: Glass Laminating Machine

Production Capacity: 72 square meter for one cycle

Place of Origin: Shandong, China (Mainland)

Brand Name: SAINT BEST

Model Number: SBT-J-2-2

Voltage: 3-Phase AC 220 V-380 V

Power(W): 15kw

Dimension(L*W*H): 3600 mm*3650 mm*2550 mm

Weight: 2200kg

Certification: CE

Warranty: 1 year

After-sales Service Provided: Engineers available to service machinery overseas

Capacity: 36square meter for 1/1.5 hours

Processing glass size: Max glass size :2000mmx3000mm

Processing glass thickness: Max glass thickness :36mm

Parameters (2000mmx3000mmx2 layers)

|

Electric Power |

(3-phase AC 220-440V)/15KW |

|

Processing Glass Size |

Max: 2000*3000mm / Min: 100*100mm |

|

|

Max bending deep(mm): 400mm |

|

|

Max glass thickness in each silicone bag: 36mm |

|

Efficiency |

Forming cycle: 75-90 Min/cycle |

|

|

Max production capacity in one cycle: 36m² |

|

|

Production capacity in 8 hours: 115m² (if 80% full furnace loaded) |

|

Operation platform |

2 layers |

|

Working Temperature |

90-140℃ |

|

Exterior Dimension |

3600*2550*1100mm |

|

Floor Space |

3700*9000 |

|

Net Weight |

2200kg |

Packaging & Delivery

| Packaging Details: | WOODEN CASE |

|---|---|

| Delivery Detail: | 20 DAYS |

Specifications

1.vacuum system wind-cooling vacuum pump,italian design

2.curved tempered laminating glass in one step.

3.self-check function

1.Vacuum system

We adopt wind-cooling vacuum pump,italian design,working stable and structure beautiful.it could continuously work for 24 hours.vacuum rate reach up to -0.09-0.098mpa.it is equipped with vacuum buffer tank,even in case of interruption of electricity,the tank double vacuum system makes vacuum faster and better.EVA Laminated Glass Equipment,Glass Laminating Machine,One Step Bend Tempered Glass Laminating Machine,EVA Laminated Glass Machine Production Line.

2.Our machine produces curved tempered laminating glass in one step,no need autoclave and pre-pressing machine.max bending height reaches 400mm.if you have autoclave ,our laminating glass equipment could work with it to produce curved safety glass easily and economically.One Step Bend

Tempered Glass Laminating Machine,EVA Laminated Glass Equipment with Germany Technology,EVA Laminated Glass Machine,PVB TPU Laminated Glass Furnace for Tempered Laminated Glass,Laminated Glass Furnace for Tempered Laminated Glass,Laminated Glass Machine.

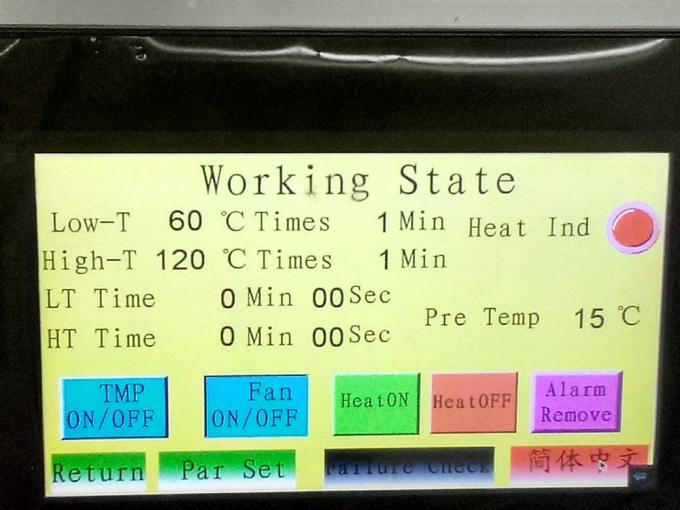

3. PLC control,all program could be completed automatically .heating time and temperature could be adjusted according to the glass thickness.working status could be shown on touch screen.

our machine has self-check function,any problems,you could also check on touch screen .it is very easy and safe to operate.EVA Laminated Glass Machine,Two Layer EVA Laminated Glass Machine,

Two Layer EVA Laminated Glass Oven,Two Layer EVA Laminated Glass Furnace,Three Layer EVA Laminated Glass Machine,Three Layer EVA Laminated Glass Oven,Three Layer EVA Laminated Glass Furnace.

4.It adopts silica gel plate which is imported from USA,thick 3mm,it could stand high temperature to 180 degree.quality guarantee period keeps 4 years in normal condition.each layer silica gel can put glass around 36mm thickness and it improves processing efficiency Three Layer Laminated Glass Machine,

Three Layer Laminated Glass Oven,Three Layer Laminated Glass Furnace,Two Layer Laminated Glass Machine,Two Layer Laminated Glass Oven,Two Layer Laminated Glass Furnace,Four Layer Laminated Glass Machine,Four Layer Laminated Glass Oven,Four Layer Laminated Glass Furnace,Four Layer EVA Laminated Glass Machine,Five Layer EVA Laminated Glass Oven.

5.Fully automatic glass lifting platform is hydraulic,more durable.it make the processing easy and safe.it needs only 2-3 workers.it greatly saves your labor cost.EVA Laminated Glass Furnace,

Glass Vacuum Heat Laminating Machine,Glass Laminating Machine Five Layers,Type 5 Wagon

Laminating Machine,Semi-Automatic Glass Laminating Machine,EVA Laminated Glass Vacuum Heat

Laminated Oven Machinery,5 Layers Glass Laminating Machine.

1.Adopts Germany independent heating technology, use stainless tube which distribute like carpet heating fast and evenly. No bubble appear

2. Process EVA film, the product yield up to 99%;

3. High efficiency, the output is 100-300 sqm in one eight-hour day;

4. Energy saving 50% compared the similar machine from other China suppliers;

5. Our machine get ISO certification ,CE certification and 5 patents.

Why choose us

1.We are manufacture, which has specialized in the laminated glass field for 13 years.

2.We welcome every customer comes to our factory for a visit

3.Free home installment and best after-sale service

4.Competitive price, high quality and quick delivery for long business

Our service

1. Your inquiry related to our product & price will be replied within 24 hours.

2. Well-trained & experienced staff are to answer all your inquiries in English

of course.

3. Working time: 8:00am - 5:30pm, Monday to Saturday (UTC+8).

4. OEM projects are highly welcomed. We have strong R&D team here to help.

5.Your business relationship with us will be confidential to any third party.

6.Good after-sale service offered, please get back if you got question.

7.For more details, please feel free to contact us. We will be more than happy

to help in anyway we can.