Manual Spacer Bar Curve Bender Manual Spacer Bar Curve Bending Machine

| Machine: | Manual Spacer Bar Curve Bender | Model: | SBT-TSW-02 |

|---|---|---|---|

| Control System: | Manual | Max Bend Diameters: | 250mm |

| Min Bend Diameter: | 120mm; | Application: | Used For Aluminum Spacer Bar Round Bending / Curved Frame Bending |

| Spacer Size: | 5.5~15.5mm |

Manual Aluminum Spacer Bar Round Bender

Manual Spacer Bar Curve Bender

Manual Spacer Bar Curve Bending Machine

Manual Aluminum Spacer Bar Round Bending Machine

Quick Details

- Condition: New

- Machine Type: Manual Spacer Bar Curve Bender

- Place of Origin: China (Mainland)

- Brand Name: SAINT BEST

- Model Number: SBT-TSW-02

- Weight: 5kg

- Warranty: 1year

-

Spacer Bar Size:5.5-15.5mm;

Min diameter:120mm;

Max diameter:250mm

Packaging & Delivery

| Packaging Details: | Standard Export Package/Carton |

|---|---|

| Delivery Detail: | 3-5days |

Description

Spacer Bar Size:5.5-15.5mm;

Min diameter:120mm;

Max diameter:250mm

Weight:5kgs

Structure

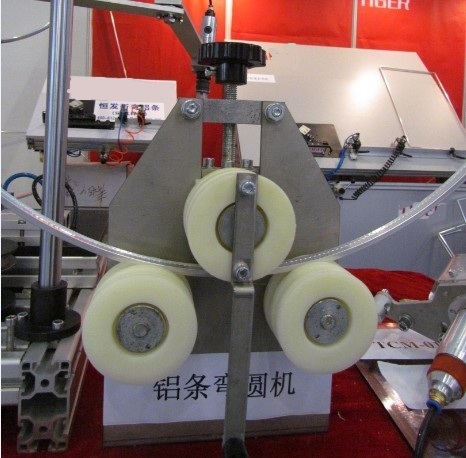

It is a bench type press rollers structure. There are three cylindrical rollers. One locates on top and two on bottom. A top hand wheel is used to rise up or lower down top roller. Rollers are heat treated and surfaces are hardened. Gears are carefully selected for durable purposes.Manual Spacer Bar Curve Bending Machine,Manual Spacer Bar Curve Bender,Manual Aluminum Spacer Bar Curve Bending Machine,Manual Aluminum Spacer Bar Curve Bender,Manual Spacer Bar Curve Bending Machine.

There is an electric motor and a gear system located beneath press rollers. They transfer transmission power and adequate torque to press rollers.

Operation

Top roller's height is adjusted. Spacer bars are put in between top and bottom rollers. By pressing a button, motor is activated to drive press rollers through transmission system. It directs spacer bar into rollers gap. Spacer bar is curved while passing rollers gap. If radius of curvature of spacer bar is small, top roller is turned downwards to narrow rollers gap with bottom rollers. If it is large, top roller is turned upwards to broaden rollers gap with bottom rollers.Manual Aluminum Spacer Bar Curve Bender, Manual Aluminum Spacer Bar Curve Bending Machine, Manual Spacer Bar Curve Bender, Manual Spacer Bar Curve Bending Machine, Manual Spacer Bar Curve Bending Machine, Manual Spacer Bar Round Bending Machine, Manual Spacer Bar Round Bender.The smallest radius of curvature the tool could curve is limited by rollers' radius. The largest radius of curvature is infinite. If radius of curvature is incorrect after curving, turn top wheel until rollers gap is adjusted to requested level. Spacer bar is driven into rollers gap again to redo the curving. This could be repeated until final radius of curvature is obtained.

This electric motorized spacer curving machine reduces workload. Spacers' radius of curvature is consistent.

Machine Processing

SAINT BEST GROUP selected each part carefully , we are strive to quality first when machine production and test each machine before delivery. So we will provide the best machine for you.Handheld manual low-e glass coating edge deletion tool, Handheld low-e glass edge deletion and coating removal removing tool and machine, manual low-e glass coating edge deletion tool, handheld low-e glass coating edge deletion tool, Handheld low-e glass coating removal machine, manual low-e glass coating edge deletion tool, manual low-e glass coating removal machine, manual low-e glass coating edge deletion machine, manual low-e glass coating removal tool .

Qualit Control

SAINT BEST GROUP engineers have years of experience in window machine fabrication, which makes the precision and stability better than others.

After machine production finished, the products will be tested in professional ways make sure its performance.

Packaging & Shipping

SAINT BEST GROUP produce high quality machines, also pay attention to package.

The machines will be packed with steel pallet and standard export wooden case,

to make sure customer will receive the machines they ordered Intact.

Our Services

Before Sale:

Free contact for the most suitable machine

Free professional design for each customer especially.

After sale service :

24 hours technical support by phone, email or skype (email or skype) .

1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Payment Terms :

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union or Paypal

A,12month warranty

B,1%-2% spare parts

C, OEM&ODM are welcomed

D,Trail orders are available

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Saint Best Group always looking for long term cooperaion, not one time deal.

Our Advantage:

Our company owns excellent team of research and development and technician which lay foundation of high-quality machine. We use are imported components and after machine production finished, the products will be tested in professional ways make sure its performance.Pneumatic Manual Low-E Grinding Machine, Manual Low-E Grinding Machine, Pneumatic Low-E Grinding Machine, Pneumatic Manual Low-E Edge Deleting Machine, Manual Low-E Edge Deleting Machine, Pneumatic Low-E Edge Deleting Machine, Pneumatic Manual Low-E Edging Machine, Manual Low-E Edging Machine, Pneumatic Low-E Edging Machine

FAQ

1. Question:Are you manufacture?

Answer:

Yes,we are the professional manufacture which have more than 5 workshops.

2.Question: About this Machine,What’s the guarantee ?

Answer:

1).Our guarantee for 12 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).We will provide the consumable parts at an agency price

5).24 hours on line service each day, free technical support.

3.Question:Why your price is higher than another company or factories ?

Answer: please check, what is is the differences of the machine of parts ,service and guarantee,especially the machine inner electric parts,

sometimes,if the machine have breakdown, the most reason is the machine inner electric parts problem,

but we use the famous and reliable parts for the machines inside.