18 Years Factory Automatic Desiccant Filling Machine - High Precision Double Edger Machine Production Line With Servo Motor – Saint Best

18 Years Factory Automatic Desiccant Filling Machine - High Precision Double Edger Machine Production Line With Servo Motor – Saint Best Detail:

| Glass Edging Machine: | Glass Double Edger Production Line | Glass Transmission Rate: | 0~8m/min |

|---|---|---|---|

| Glass Diagonal Error:: | ±0.5mm/㎡ | Thickness Of Process Glass: | Standard 3~25mm |

| Number Of Motors: | 24 | Certification: | CE/ISO9001:2008 |

Quick Details

- Condition: New

- Machine Type: Glass double edger production line

- Production Capacity: 12 sets/month

- Place of Origin: Guangdong, China (Mainland)

- Brand Name: SAINT BEST

- Model Number: SBT-BYL4525

- Voltage: 220/380V/480 50Hz/60Hz 3P

- Power(W): 103Kw

- Dimension(L*W*H): 18500*10000*2800mm

- Weight: 18000kg

- Certification: CE

- Warranty: 1 Year

- After-sales Service Provided: Engineers available to service machinery overseas

- Grinding motor supplier: Shanghai ABB

- Glass transmission rate: 0~8m/min

- Thickness of process glass: Standard 3~25mm

- Width of glass chamfering: 0~3mm

- Number of motors:24

- Error of glass chamfering width: ±0.2mm/m

- Error of glass paralle: ±0.2mm/m

- 6 Motors Glass Double Pencil Round Edge Grinding Machine / Pencil Glass Double Edge Edger

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | Shipped in 60 days after payment |

Product Description

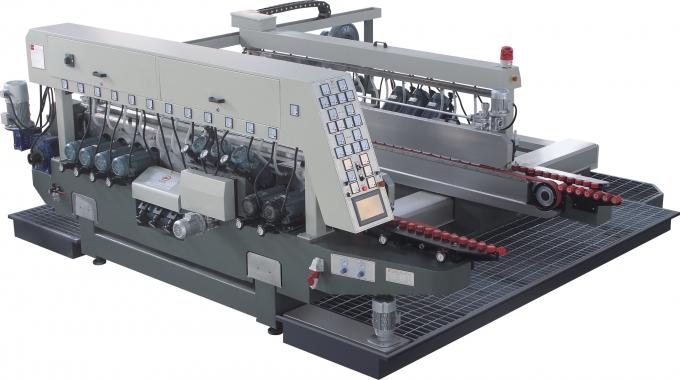

SBT-BYL4525(24 motors)

Feature:

1) oil lubrication full automatic including all motor slide plate

2) one option or push button use to retrack or move backward all polishing spindle.

3)opening/ closing using gear-rack.

4)Drive using 2 sets 3KW servo motors.

5)opening/ closing using 1 set 1.5KW servo motors.BYL4525(24 motors)

1.The first Double Glass Edging Machine:SBT-BYS4524

and

2.The second Double Glass Edger:SBT-BYS2524

the number of motors :24 motors (depends on the customer's requirement)

the width of glass chamfering : 0~3mm

The thickness of process glass :3~25mm

The error of glass parallel: ±0.2mm/m

The error of glass chamfering width: ±0.2mm/m

Glass diagonal error : ±0.5mm/㎡

Width positioning error: ±0.1mm/㎡

Glass transmission rate : 0.5~8m/min

Power source:380/3ph/50Hz ( depends on the customer's requirement)

Glass double pencil edger,6 motors glass double pencil round edge grinding machine,8 motors glass double pencil round edge grinding machine,10 motors glass double pencil round edge grinding machine,Glass double round edging machine,10 motors glass pencil round double edge grinding machine

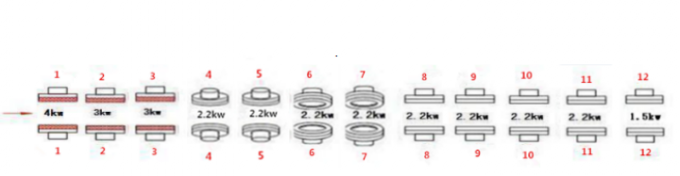

Arrangement of grinding wheels and distribution diagram of motor power

Arrangement of grinding wheel and distribution diagram of motor power

No.1 No.2 No.3 No.4 No.5 No.6 No.7 No.8 No.9 No.10 No.11 No.12

100# 140# 180# 240# 10S40 240# 10S40 240# 240# 10S40 10S40 10S40

Diamond Diamond Diamond Resin Taxus Resin Taxus Resin Resin Taxus Taxus Taxus

wheel wheel wheel wheel wheel wheel wheel wheel wheel wheel wheel wheel

Main Features

The minimal size of the common process glass is 160mm*160mm,minimal thickness 2mm.The thickest size depends on the requirements and the quality of grinding wheel..Glass double pencil edger,6 motors glass double pencil round edge grinding machine,8 motors glass double pencil round edge grinding machine,10 motors glass double pencil round edge grinding machine,Glass double round edging machine,10 motors glass pencil round double edge grinding machine,12 motors glass double pencil round edge grinding machine,14 motors glass double pencil round edge grinding machine.

This machine has the advanced structures,precision components,exquisite assembly technology,good fittings,stable property,excellent quality,easy operation and simply maintenance.

Processing glass diagonal error within 0.5 mm,parallelism error within 0.1mm,chamfering balance,clear angles,no collapse edge, round edge phenomenon.10 Motors Glass double pencil edger,8 motors Glass double pencil edger,6 motors Glass double pencil edger,12 Motors Glass double pencil edger,14 motors Glass double pencil edger.

It is suitable for processing all kinds of high-grade sealed insulating glass and appliances glass.Can be extended the laser code then identify the automatic control.Glass Straight-line Turning Table,Glass automatic Turning Table,Glass Automatic Turning Table.

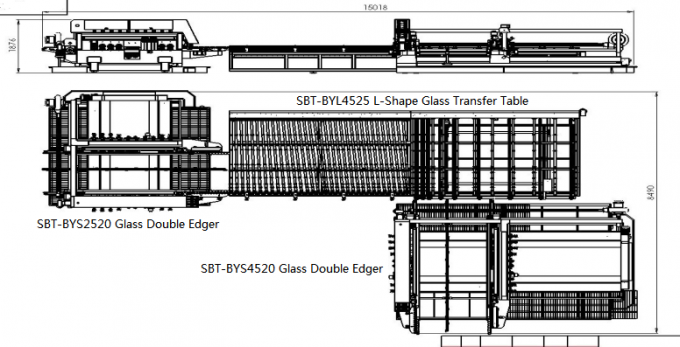

3. L-shape transfer table (SBT-BYL4525)

SBT-BYL4525 L-shape glass double-deck turning table is bilateral glass edge grinding machine ( right angle arrangement) in the middle of the directional control unit. The machine transmission device is divided into two layers, the bottom and top layers of transmission direction perpendicular to each other. The processing glass enters through the feed end and is processed by the first glass double straight edge grinding machine. After this, the glass is turned 90degree through the glass automatic reversing station. And then it is delivered to the feed end of the second set of glass double straight edge grinding machine and complete the other two sides edge grinding processing.Transittransport all actions by the first double edger control, without artificial assistance.glass tempering furnace,glass double edging machine,glass straight line beveling edging machine,glass straight line edging machine,glass straight line multilevel edging machine,glass washing machine,glass drilling machine,glass irregular shape machine,glass automatic sandblasting machine,glass chamfering machine and glass automatic cutting machine,glass automatic loading machine.

Main Technical Parameters:

| No. | Items | Parameters | Remarks |

| 1 | Max glass size/mm | 4500×2500 | Can be customized according to customer requirements |

| 2 | Min glass size/mm | 200×200 |

The minimum size can transit :70mm×70mm |

| 3 | Thickness of glass/mm | 3-25mm | |

| 4 | Glass transmission rate | 0.5-34 m/min | |

| 5 | power | 3.5 KW | |

| 6 | Power source | AC380V 50HZ |

Glass Samples

Our Factory

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent excellent management throughout all stages of creation enables us to guarantee total buyer satisfaction for 18 Years Factory Automatic Desiccant Filling Machine - High Precision Double Edger Machine Production Line With Servo Motor – Saint Best , The product will supply to all over the world, such as: Barbados , Russia , Chicago , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.